Management Policy

Observing laws and regulations, scientific management, improving quality, energy conservation and consumption reduction, pollution prevention, environmental protection production, information security, continuous improvement, supplying excellent products and services for society and customers.

Management System

eQ-3 has a vision of "continuously providing high-quality and innovative products to become a world-class home intelligence enterprise". Our management systems included quality management system, environmental management system, and hazardous substance process management system and information security management system. eQ-3 has fully passed ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and ISO 27001 information security management system certificate. eQ-3 according to ISO 9001:2015, ISO 14001:2015, QC 080000:2017 and ISO 27001:2022 standards and has established a comprehensive internal management system, including raw material procurement, product manufacturing, and product testing. Adhere to meet customer needs as the starting point, with the overall optimization of the entire production process as the goal, and achieve management technology for full process control.

Quality Objectives

1. IQC DPPM ≤DPPM 2000

2. Molding QC DPPM ≤DPPM 1200

3.Spray /Silk printing QC DPPM ≤DPPM 800

4.Assembly PQA DPPM ≤DPPM 1000

5.SMT QC DPPM ≤DPPM 100

6.First Pass Yield of assembly workshop≥92%

7.Repair rate of Assembly workshop by Qty ≤1.0%

8.Customer complaint ≤2 times/month

Quality Control Process

Our company's quality control process includes supplier management, incoming quality control, in-process quality control, outgoing quality control, and quality system control, which together constitute our company's closed-loop quality control system.

Supplier management

Including supplier selection and qualification evaluation, supplier material approval, quarterly and annual assessments of supplier delivery quality, delivery, and cooperation, and regular on-site audits of suppliers etc.

Incoming quality control

IQC conducts sampling inspections on the appearance, dimension, performance, packaging, and environmental requirements of incoming materials according to inspection documents to ensure that the quality of incoming products meets our specifications and environmental requirements.

Process quality control

Including injection molding process, SMT process, silk screen& laser process, finished product assembly process, packaging process, and warehouse handling quality control. Each QC section of the process conducts first article inspection, in-process sampling inspection, and final sampling inspection on the materials used, product appearance, structure, dimension, performance, and environmental requirements according to the inspection documents to ensure that the quality of the produced products meets our specifications.

Outgoing quality control

Including finished product inspection, product related reliability testing and verification etc. PQA conducts first article inspection, in-process sampling inspection, and outgoing sampling inspection on product appearance, structure, dimension, performance, and environmental requirements according to inspection documents to ensure that the quality of the shipped finished products meets customer specifications. Product reliability testing verification includes new product reliability verification, such as product packaging reliability verification (vibration and drop test), high and low temperature verification, tumbling barrel test etc; Reliability verification of mass-produced products refers to conducting relevant reliability tests according to product specifications, such as lifetime test, aging test etc., to ensure that the product meets the design and use requirements.

Quality system control

Including quality system management, document control, customer service, quality planning, quality training, quality activities, etc.

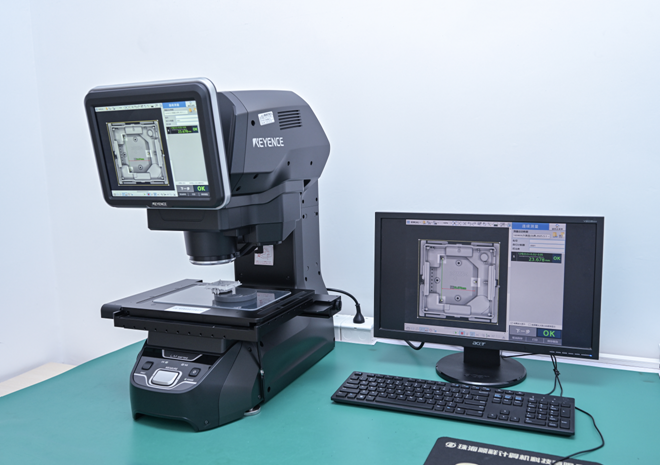

Quality Inspection Equipments

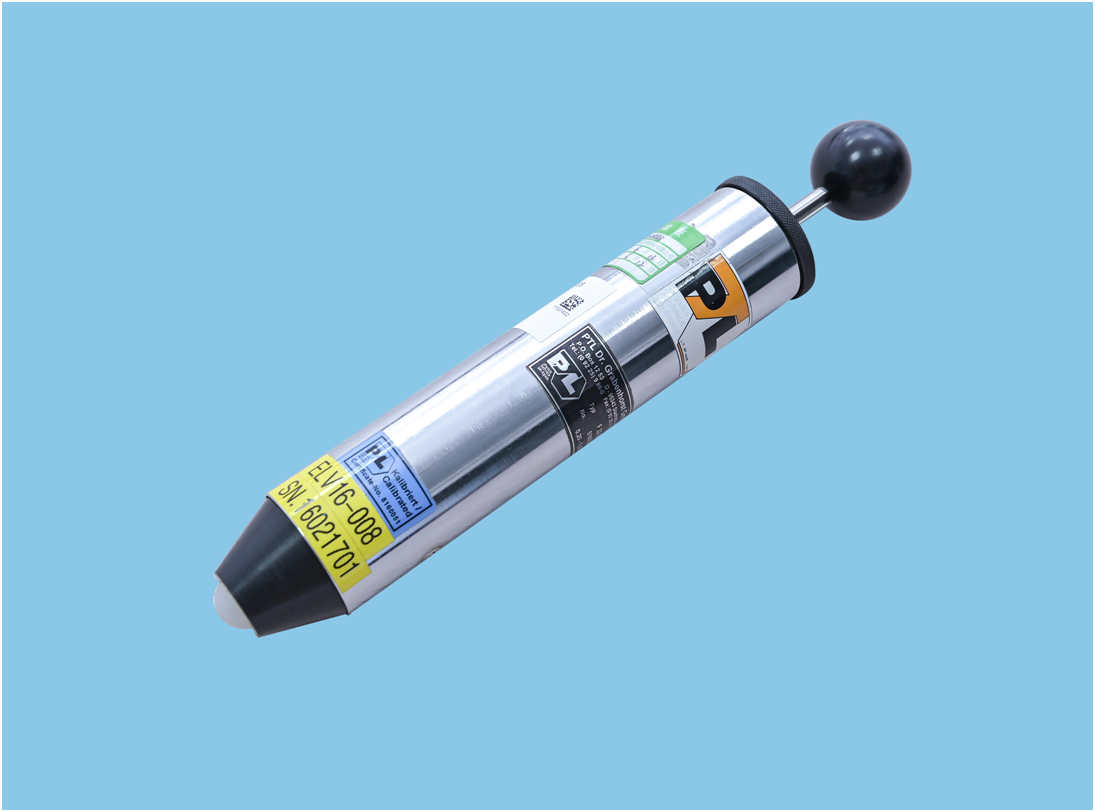

Quality inspection equipment plays a crucial role in ensuring product safety and quality. eQ-3 factory is equipped with high-precision smoke alarm sensitivity testers, 2D measuring machine, 3D scanning measuring machine, tumbling barrel test machine, high and low temperature testing machine, XRF tester and other inspection equipment, which can fully meet the requirement of product measurement and testing.

High-precision smoke alarm sensitivity tester

2D measuring instrument

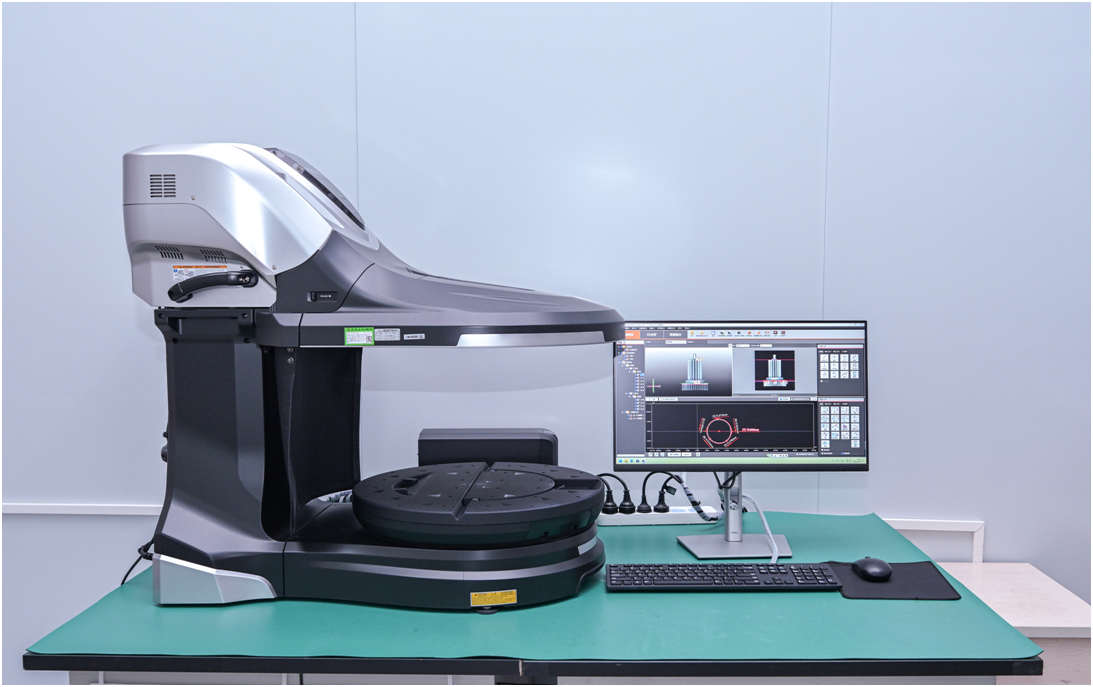

3D scanning measuring instrument

XRF fluorescence analyzer

SMT first-piece test instrument

High and low temperature test chamber

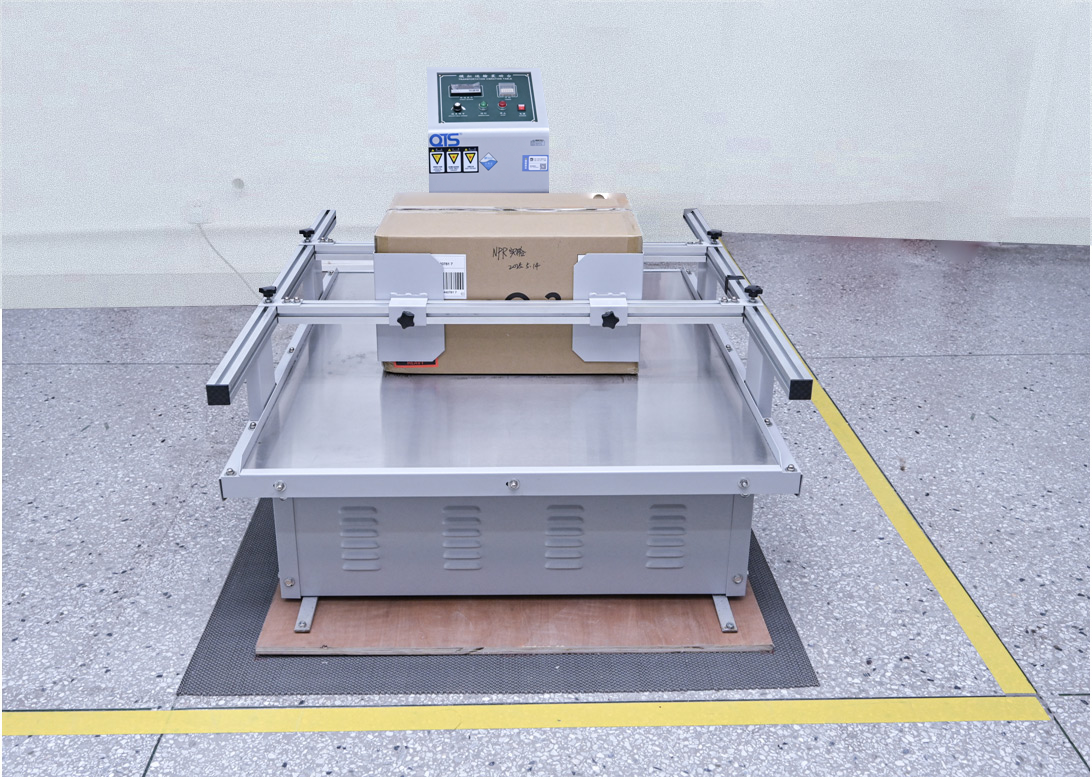

Vibration tester

Tumbling drum tester

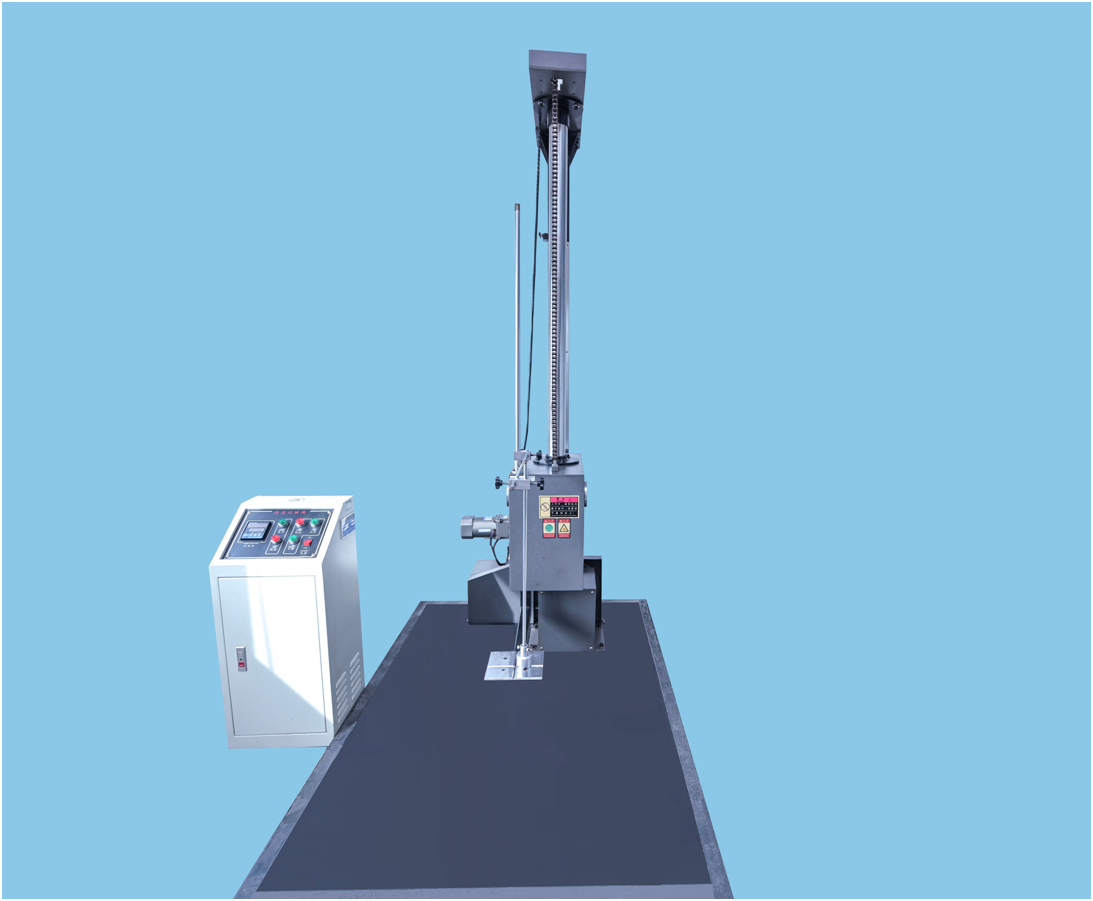

Drop tester

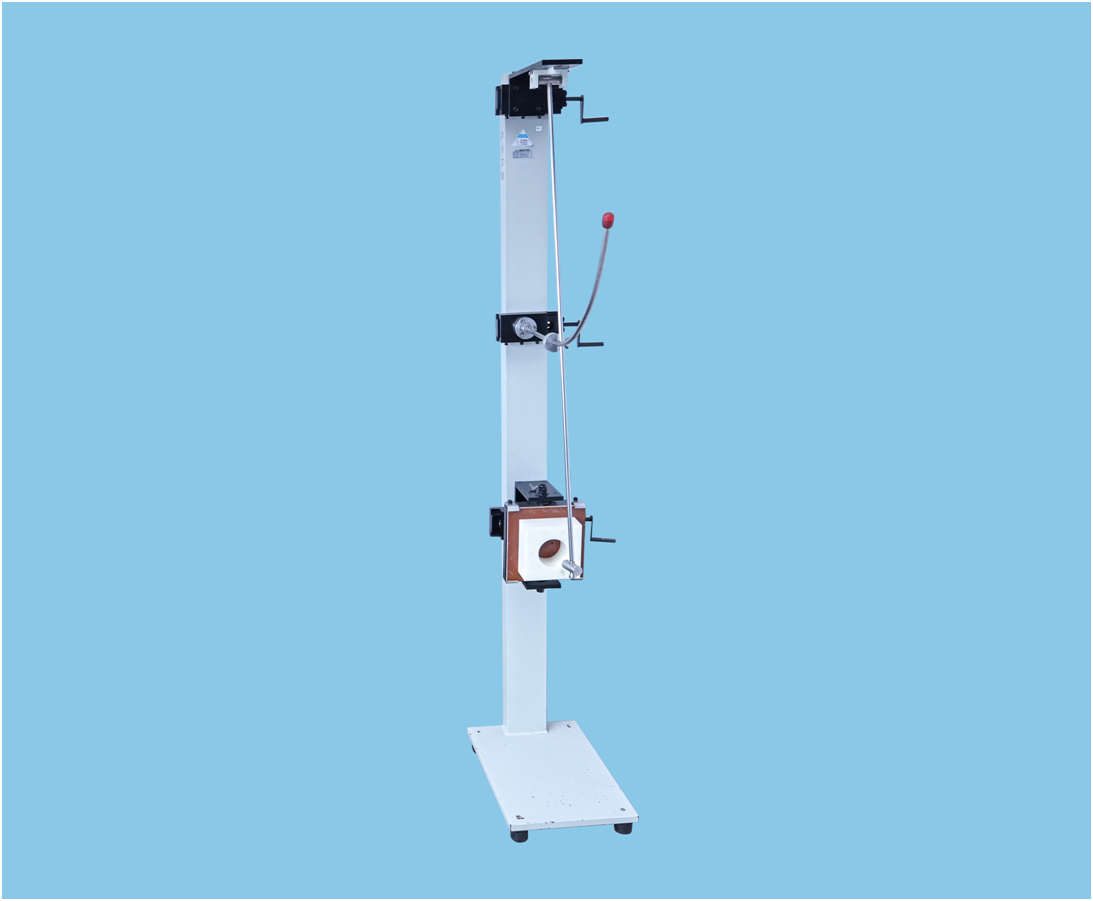

Pendulum impact tester

Quiet test room

Salt spray test chamber

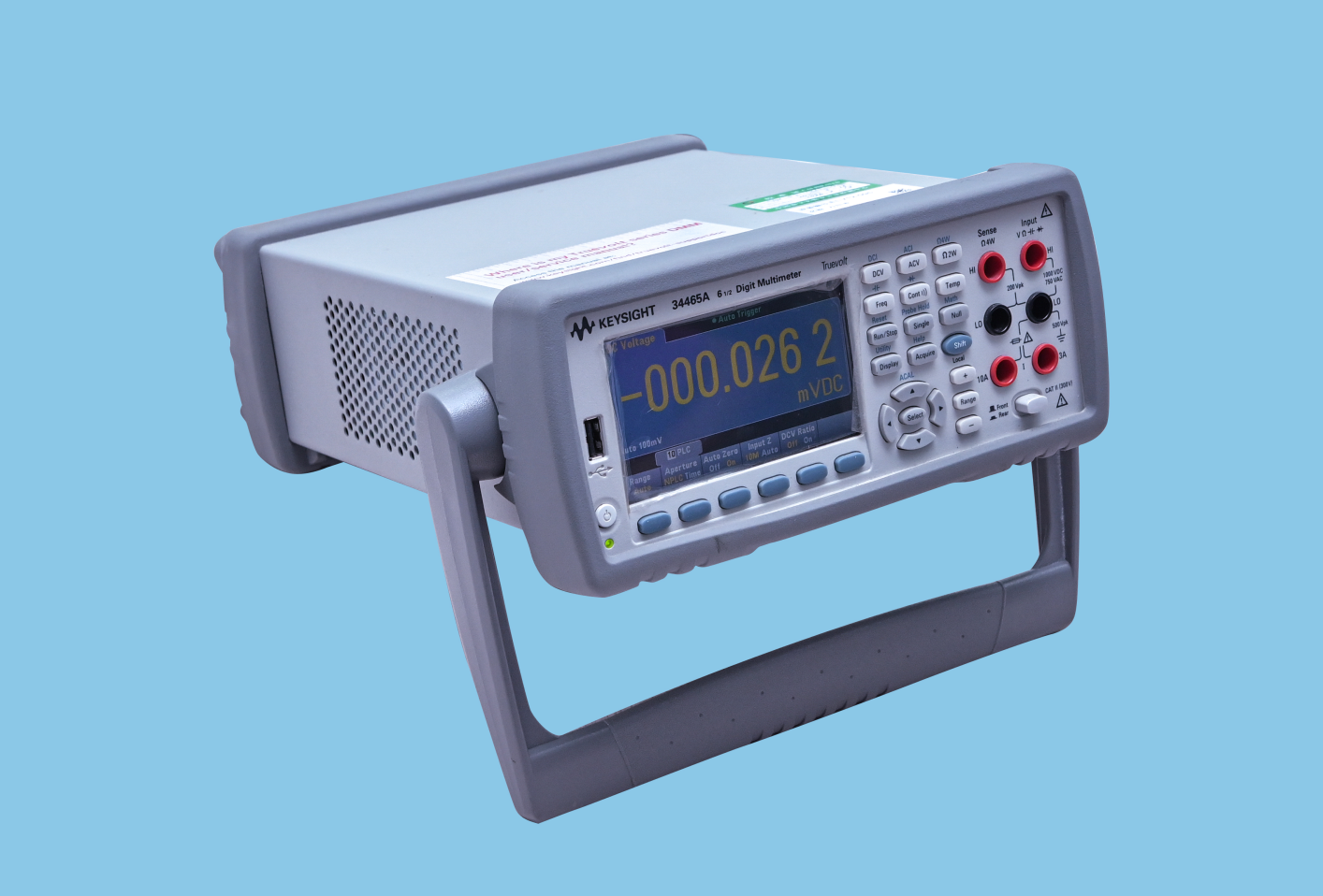

Agilent digital multimeter

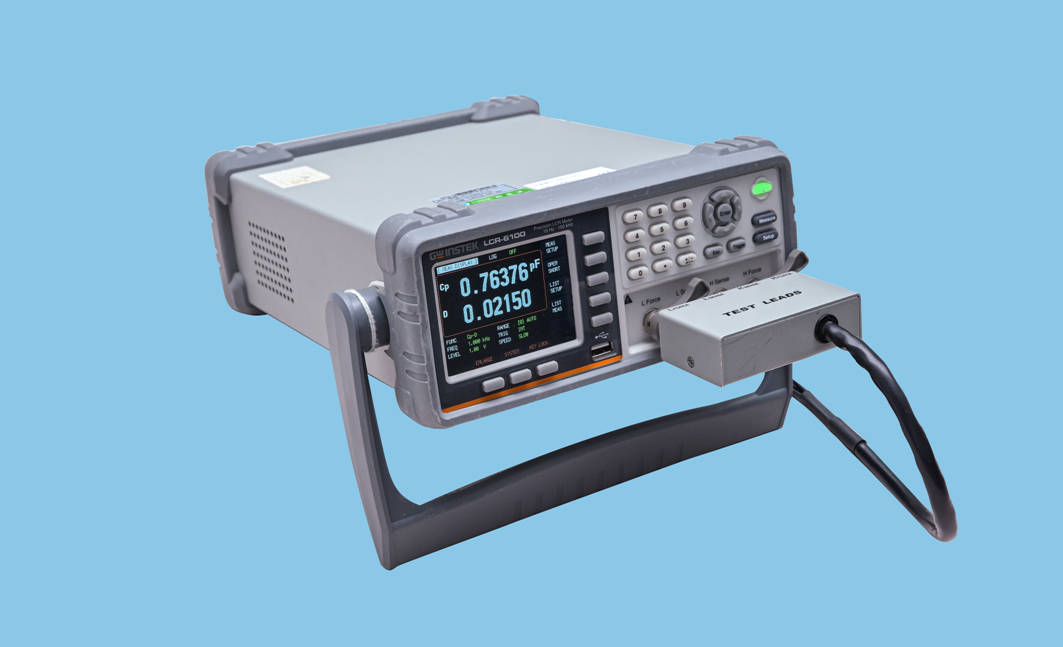

LCR meter

Safety regulation tester

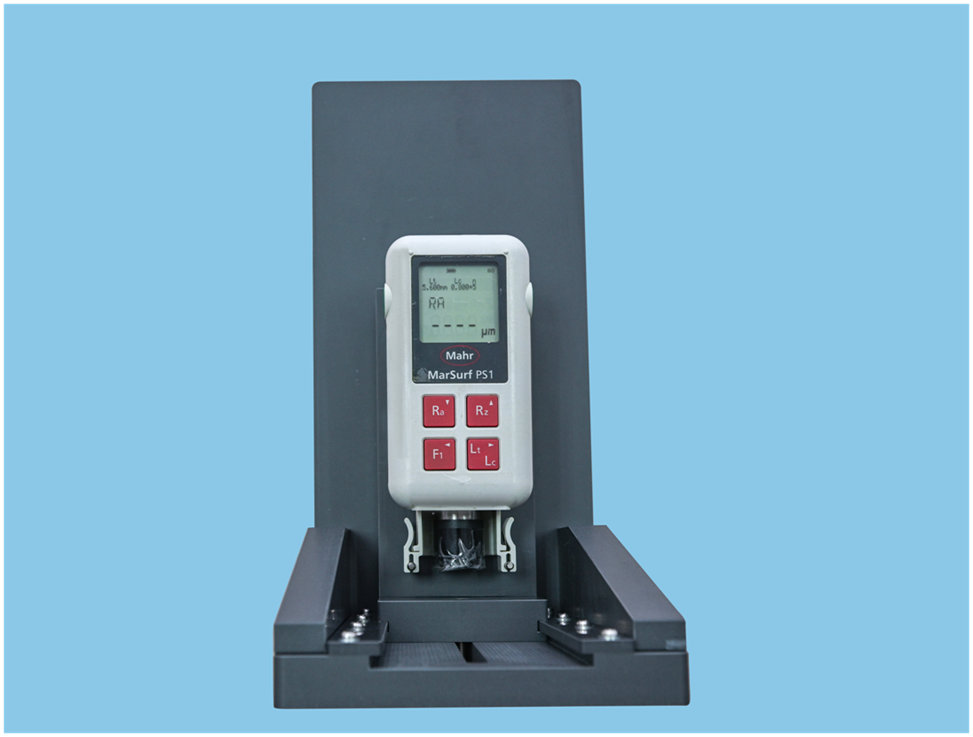

Surface roughness measuring instrument

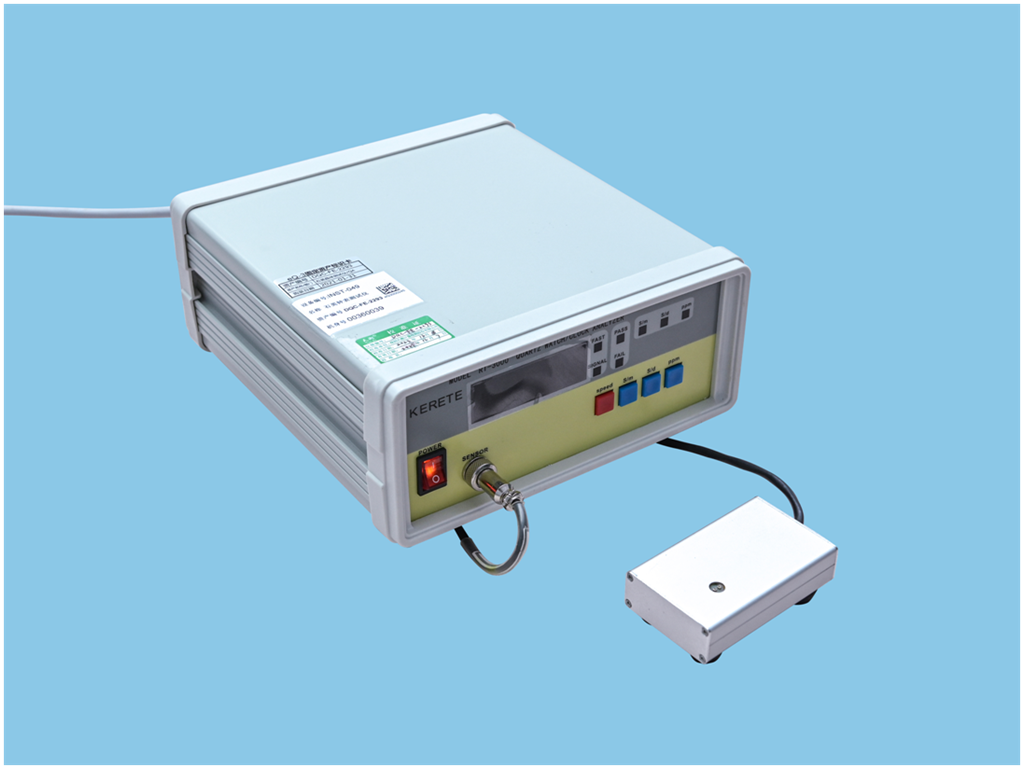

Huimei spectrum analyzer

Quartz watch tester

Color measuring meter

Spring impact hammer

Digital oscilloscope

Certificates

Our company implements management systems such as ISO 9001, ISO 14001, ISO 27001, QC080000 etc., and has passed ISO 9001, ISO 14001, ISO 27001 certifications. Our products have passed certifications such as VdS, VDE, TÜV, Kriwan etc.